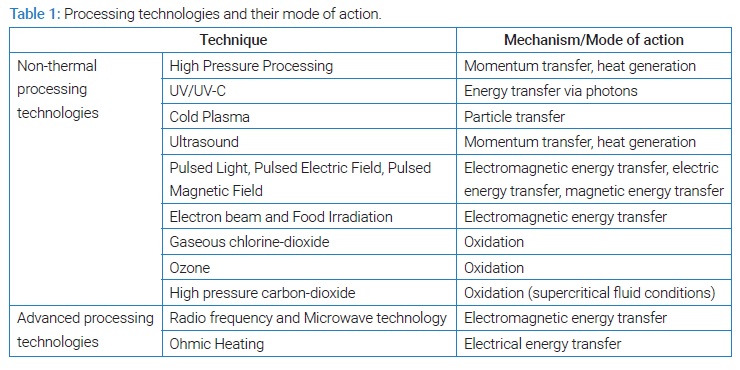

Non-thermal processing technologies

Due to growing awareness of consumer on harmful effect of processed food products produced using chemical preservatives and apply severe heat treatment for longer time to achieve commercial sterility. Therefore, consumer now demands high quality foods which are more convenient, minimal processed, more natural, fresher, and healthier and contains less/no preservative. Researchers and industries responded this demand and developed new and improved physical process techniques for example, high pressure processing, ultrasonication, irradiation, cold plasma and pulse electric field etc.,

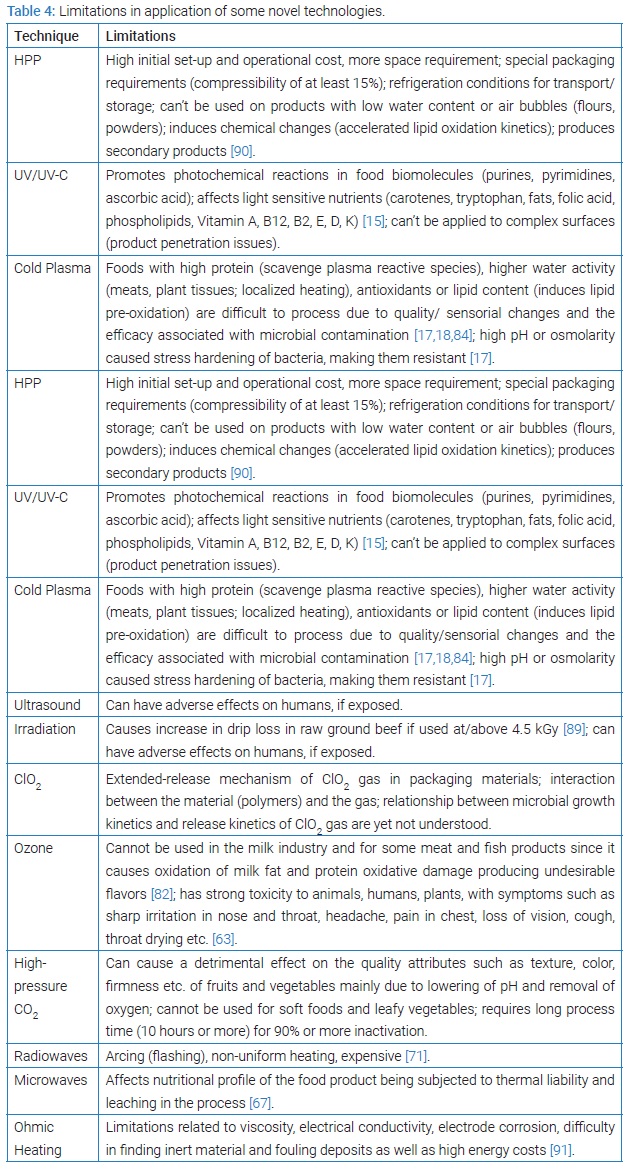

High Pressure Processing (HPP): HPP, also known as ‘cold pasteurization’ is a technique where the sealed/pre-packaged food products are kept in a vessel and subjected to pressures usually between 300 MPa to 600 MPa via purified water for short time, at cold/low temperatures. The high pressure causes the inactivation of bacteria, vegetative cells of viruses, bacteria, yeasts, molds and parasites and also inactivate food enzymes (polyphenol oxidase, lipoxygenase), reducing undesirable changes mainly due to structural rearrangement of proteins, since there is no breakage of covalent bonds [2–5]. The main forces/ bonds affected by pressure are van der Walls forces, electrostatic interactions and hydrogen bridges [3]. Efficiency of HPP can be improved by optimization of process parameters: temperature, pressure applied, holding time in the vessel, targeted micro-organisms and pathogens and food composition (proteins, lipids, carbohydrates, added solutes and water activity, induce shielding effect) [6].

HPP can be implemented on heat sensitive foods as well as ready to eat, ready to cook meats (especially dry-cured), fruits and vegetables, juices, coconut water, smoothies, soups and sauces, wet salads and dips, dairy products, aquatic produce pet foods, baby foods etc., HPP helps in better retention of amino acids after pasteurization for (5–10)minutes [7,8]. HPP is much more effective against high acid foods. Pressure Assisted Thermal Sterilization (PATS) is used for low Acid Foods (FDA). When high pressure (about 600 MPa) is combined with high temperature (100°C), it can be used for Pressure Assisted Thermal Processing (PATP) for the sterilization of foods [3,9]. The time dependent changes associated with food such as enzyme kinetics and microbial inactivation can be monitored via application of temperature measurements, temperature distribution associated numerical simulations and use of pressure-time-temperature indicators [3]. Further, microbial death probability calculated by kinetic equations and models such as Weibull model and Baranyi equation can be used to understand the relative death rate and in turn effectiveness of the used HPP/PATP technology at certain time-temperature-pressure combinations for inactivation of bacterial spores such as C. perfringens, C. sporogenes etc., [3]. HPP treatment (100 MPa to 500 MPa) can induce enzymatic hydrolysis of glucosinolates, yielding isothiocyanates, some of which have health promoting properties [10]. It also enhances the nutritional profile of brown rice by causing cell wall disruption, resulting in increased mass transfer rate of solvents, which causes enhanced catalytic reaction effect of glutamate-decarboxylase on glutamic acid and increasing the concentration of γ amino butyric acid inside brown rice [7]. HPP is also used for the extraction of collagen from fish skin, flavonoids from propolis, anthocyanidin from grape skin, triterpenes from Antrodia cinnamomea and ginsenoside from ginseng root proving its potential application in health and biotechnology industry [7]. US FDA has approved HPP to achieve 5-log reduction in E.coli O157:H7 (1.9 MPa to 2.3 MPa) and eliminate Listeria monocytogenes in processed meats [7,11,12]. It also accelerates tenderization and ageing process on meat via increased enzyme (protease) activity. HPP also promotes wine ageing characteristics (color, pH, acidity and turbidity) and can inhibit the growth of lactobacillus, acetobacter and yeast without the usage of anti-bacterial agents such as sulfites [7,13]. Further, it has been seen that the HPP processed products have a better consumer acceptance than the usual thermally processed foods due to better quality retention for a longer time when stored under refrigeration conditions with pH < 4.5 or reduced water activity [3]. The expected market for HPP foods is expected to reach around $54.77 billion in 2025 [7].

UV/UV-C: Ultraviolet-C light technique possesses germicidal properties without causing any significant damage to the food products. The inactivation efficiency of UV-C, when put on a graph, forms a bell shaped curve showing maximum inactivation between 254 nm to 264 nm, thus 254 nm is the usually selected wavelength for UV-C produced by low/ medium pressure mercury arc-lamps yielding monochromatic or polychromatic radiations in the UV and visible light range [14,15]. UV-C light that gets absorbed in the food penetrates into the outer cell membranes of cells, reaches the DNA and causes significant damage due to the formation of thymine dimmers, preventing microorganisms to undergo transcription and replication, eventually leading to cell death [14]. It promotes the production of phenylalanine ammonia-lyase (responsible for the generation of phenolic compounds like phytoalexins) in fruits and vegetables imparting them increased resistance [15]. Development of UV-based process that is product specific requires quantizing the dose essential for the effective delivery of the energy for a particular target organism on a particular food system (UV transmission rates) that, for now, has no specific amount (or limit) pertaining to any product and varies with the desired outcomes. It can be optimized with product attributes such as composition, coefficient of absorption, rheological properties, initial microbial load, and reduction requirements as well as the final nutritional, sensory and quality parameters including the effects it will have on the internal components such as enzymes and flavour compounds. It can enhance nutritional components such as anthrocyanins in cherries, apples, strawberries, ascorbate peroxidase in melon and resveratrol in grapes etc., [15]. It has been approved by US-FDA (juice products), Health Canada (apple products such as juice and cider), and European Food Safety Authority and Israeli food regulations agency (pasteurized milk).

UV light initiates or catalyses the stages associated with oxidation processes, including the free radical oxidation. The resultant ions formed are: lipid radicals, superoxide radicals and hydrogen peroxide. These superoxide radicals further induce cross-linking of carbohydrates, fragmentations of proteins/DNA [15], per-oxidation of unsaturated fatty acid, and loss of membrane fluidity function. It can cause denaturation of proteins and enzymes in milk and can form OH− and H+ radicals in water, which can react with other food components of the food material [14]. UV light can be effectively used in the inactivation of microbes such as S. aureus, B. cereus, A. flavus, L. monocytogenes,, A. niger, P. corylophilum, E. rubrum, M.fructicola, P. digitatum, E.coli, S. typhimurium, R.stolinifer, yeasts and molds etc., in food products such as peach, sweet potato, tomato, tangerine, corn, kiwi, lemon, pears, raspberries, oranges, chicken frankfurters, chicken breast, milk and juices etc., [15,16].

In the latest UV technology, the liquid is pumped inside a polymer tube (food grade) in a turbulent flow regime (depending upon the size and geometry of tube + product flow rate). The light photons are supplied to the entire volume of the liquid pumped through the tube (food grade). The compounds selectively absorb the light and in presence of oxygen cause local cytotoxic reactions and selectively harm the microbial cell. Photocatalyzation (using titanium oxide) and photoactivation (using zinc oxide) are also emerging technologies related to UV application. The oxides may be attached or incorporated into the packaging material for food contact applications. For the safe processing of foods, US FDA has approved the use of low mercury lamps emitting 90% of the light at 253.7 nm wavelength for effective treatment of product such as mushrooms, bread, baker’s yeast etc., [15,17]. Another latest development in the UV technology is the use of High-intensity UV Light Emitting Diode (LED) technology (e.g. Phoseon) for reduction of pathogens for manufacturing processes where disinfection and decontamination are required. It targets the DNA, RNA, and protein specific bonds in micro-organisms and biomolecules via high irradiance combined with appropriate wavelengths, allowing for concise time for inactivation while improving overall disinfection efficacy.

Cold Plasma: It is created by the ionization of gas (partial or complete), usually at atmospheric/partial pressure via sources such as heat, electricity, radiation, rapid compression etc., [18]. Plasma is made up of free electrons, neutral molecules, radicals and ions which further generate variety of products. On ionization of air/ feed gases containing oxygen, the resulting plasma contains multiple oxygen ions such as O2+, O2−, O3, O, •O, O+, and O−, oxygen in the metastable state and ionized ozone. Cold plasma system operating at room temperature and atmospheric pressure is called Atmospheric Cold Plasma (ACP). Effective treatments can be achieved in time range of 120s to 3s depending of the process conditions and the food that needs to be treated [18].

There are three types of process application of cold plasma system for food: (i) remote treatment, (ii) direct treatment and (iii) electrode contact system, depending upon the treatment conditions and mode of application [18–22]. The efficiency of plasma can be increased by application under modified atmosphere with lesser ionizable gases (e.g. oxygen), or magnetic field or by supplying chemical components such as hydrogen [18,23]. It can activate enzymes such as catalase, lipase and superoxide dismutase, induce the reduction of polyphenol-oxidase, peroxidase, lysozyme, alkaline phosphatase, pectin methylesterase, α-chymotrypsin as well as anthrocyanins in foods such as tomatoes, carrots, lettuce, kiwi and blueberries etc., reducing browning and undesirable color changes [17,24].

The primary mechanisms by which the cold plasma inactivates the micro-organisms: (i) Reactive species chemically interacting with the cell membrane of microbes, releasing the stored energy; (ii) Interactions that cause cell membrane damage and injury to the internal components of the cell (iii) The re-coupling of ions/species cause the breakage of the DNA strands. Inactivation of gram-positive bacteria (S. aureus) is attributed to the intercellular and little envelope damage whereas for gram-negative bacteria (E. coli) it is attributed to cell leakage and low-level DNA damage [25]. It has also been found to degrade the chemical residues of agricultural pesticides such as parathion, paraoxon, omethoate, malathion etc., to less-toxic or safe chemical structures and also promotes the seed germination and plant growth [17,26]. Further, this technology has an excellent anti-biofilm activity affected by factors such as gas composition, attachment surface, processing parameters, types of bacteria, biofilm thickness etc., that can control the challenges of food safety [27]. It is effective against pathogenic bacteria such as E. coli O157:H7, L. monocytogenes, Salmonella, Shigella, S. aureus, A. niger, B. subtilis, S. cerevisiae, D. radioduran, S. typhimurium, C. jejuni viruses such as Tulane in romaine lettuce, and parasites etc., [18,28]. It can also be used for insect control in stored commodities and for the degradation of mycotoxins (such as aflatoxins, fumonisin, zearalenone, Deoxynivalenol etc.,) and mycotoxin producing fungi (such as Aspergillus, Alternaria, Fusarium and Penicillium) especially in seeds, grains and crops as well as for the reduction of allergens (tropomyosin, glycinin, trypsin inhibitor) in products such as soybean (due to the reaction with ROS and RNS present in the plasma) [17,27,29]. It can also be used to modify the functionality of foods containing components such as starch and proteins by inducing conformational and configurational changes [23,30]. A number of chemical reactions such as oxidation of sugars to acids (degradation of oligosaccharides in juices), amino acid modifications in proteins, protein structural loss, per-oxidation of lipids (especially in fish) and unsaturated fatty acids have been observed in products after treatment [17,28]. Future applications include hydrogenation of edible oils, treatment of food industry effluents as well as food waste processing [22,31,32].

Plasma for packaging treatment: Cold plasma induces various physical and chemical processes on the plasma-polymer interface that may be utilized to impart surface energies (selective and tunable) to the polymers used for packaging in surface fictionalization, thus modifying them. This will promote properties such as barrier and migration, adhesion/anti-adhesion, hydrophobicity, seal ability, printability and ability of the polymer to resist mechanical failure [33–35]. Micro-organisms that adhere to the polymer surfaces can also be inactivated via reactions induced by gas plasma. But the loss of these properties, termed as ‘ageing’, can occur in the treated materials over time, which is attributed to inward-diffusion, agglomeration or sublimation of low molecular weight organic molecules, repetition or reorientation of polymer chains and migration of additives from bulk to surface [35]. It can be reduced by the use of gases like methane and oxygen or any other viable mixture of gas for cold plasma treatment. Treatment with cold plasma is used for sterilization of packaging materials and in-package plasma decontamination of materials such as PET foils, polystyrene, polyethylene (LDPE, HDPE), polypropylene and multi layer packaging based on PET/PVDC/LDPE and also for the immobilization of anti-microbial substances such as chitosan, sliver and trichlosan on the films [35,36]. It has been proved effective against the micro-organisms such as E. coli, L. monocytogenes, S. aureus, P. aeruginosa etc., [35].

Plasma-Activated Water: A chlorine alternative: In this, reactive chemical species in the cold plasma treatment are seized in water, either in solution (plasma activated water, PAW) or in discrete fine droplets (plasma activated mist, PAM). These are relatively longer-lived reaction products that can mimic conventional chemical sanitizers in water without the addition of chlorine which can be retained and are usually the secondary products such as hydrogen peroxide, nitrates and nitrites that upon internal reactions may generate toxic chemicals such as peroxynitrous acid [17,32,37]. For PAW, the generated plasma is injected into water and the generated product is used as a spray, wand or fogger system. For PAM, water droplets are passed through a dielectric barrier discharge or plasma jet and can be used as a spray or a drench or stored in a tank for later usage, especially by generating aqueous sanitizing solution. Although the effectiveness (with time) of PAW is under research especially for the fresh products (cut or ice-packed) and seafood, it has been shown that it extends shelf life of the treated products. This is attributed to the reduced rate of recombination reaction for the products kept in the refrigerated solutions. It can be used to treat liquid effluent from various industries for the purpose of decontamination [17].

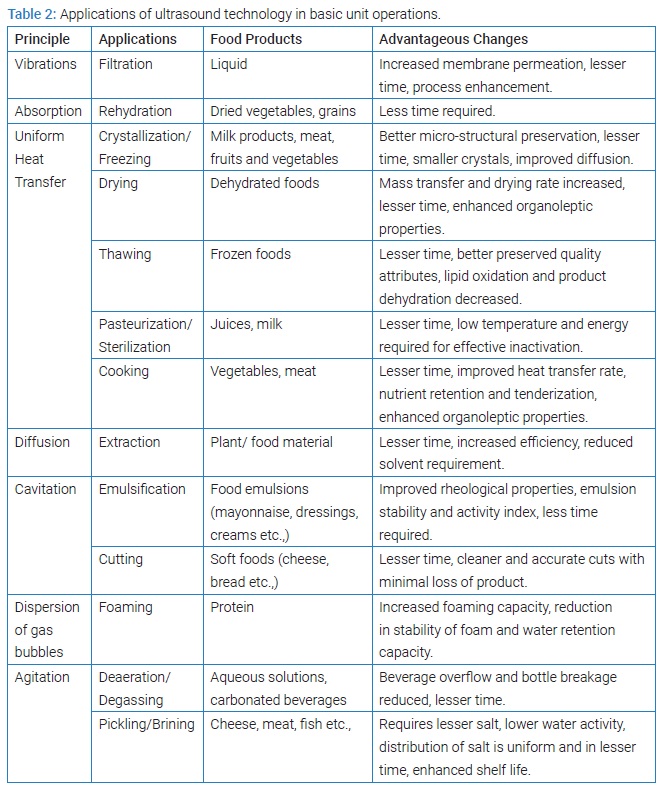

Ultrasound: Ultrasounds (frequency above 20 kHz) are created when electrical pulses are converted into acoustic energy by a transducer (magnetostrictive/piezoelectric). A force is generated when these waves bombard the food product surface, shear wave (surface is parallel to the direction of force) or compression wave (surface is perpendicular to the direction of force), which inherit attenuation (due to energy loss during compression/decompression) while crossing through the food product. This generated force produces very rapid changes in pressure (up to 1000 atm) and temperature (up to 5000 K), developing a lethal-effect on the microorganisms by the virtue of changes such as shear disruption, turbulence, cavitation (creation of bubbles in liquid foods), thinning of cell membrane, localized heating and production of free radicals. Stable cavitation is a result of bubbles maintaining a stable increase and decrease in size which results in the medium’s micro-agitation which further leads to transient cavitation [38]. The cavitation effect and its intensity can be optimized by process variables like intensity, pressure, applied energy, frequency of the ultrasonic waves, viscosity of medium etc., [38]. These waves can be used directly onto the products producing a ‘sponge-like’ effect that overcomes the inter-capillary shear forces to release of liquid from the inner parts of the particles to the solid surface or the incorporation of fluids from outside [38]. Cavitation effects around the surface of the product are also responsible for the formation of microjets responsible for mass transfer of components if the threshold limit is overcome [38]. Its types include thermosonication (temperature used) and manosonication (pressure used) along with sonication that enhances the efficacy due to generated synergistic effects [39].

Depending upon the intensity and frequency, the ultrasound waves and their use can be of two types [39,40]:

Low intensity/High-frequency ultrasound: frequency range >100 kHz and intensity <1 W/cm2: used for food product’s structural evaluation (shape, size, dimensions), determination of food composition of fresh commodities (meat, poultry), and for non-invasive and non-destructive analysis of food products as well as quality regulation and control of fresh produce (meat, fruits, vegetables) and cereals, fats and emulsions, aerated foods etc.,

Principle of operation: interaction between matter and high frequency sound waves is used to obtain the structural inferences and physico-chemical attributes, foreign bodies and defects in packaged foods determined by the absorption characteristics of the materials (homogeneous and heterogeneous).

High intensity/Low-frequency ultrasound: frequency range: 20 kHz to 100 kHz and intensity range: 10 W/cm2 to 1000 W/cm2: used in emulsification, defoaming, regulation of microstructures and modification of textural attributes of fatty products, sono-crystallization, and enhancing functional properties of food proteins. Other applications areas include freezing, drying, tenderization, concentration, thawing, emulsification etc.,

Principle of operation: Production, growth and collapse of large bubbles induce acoustic cavities which liberate high amount of energy.

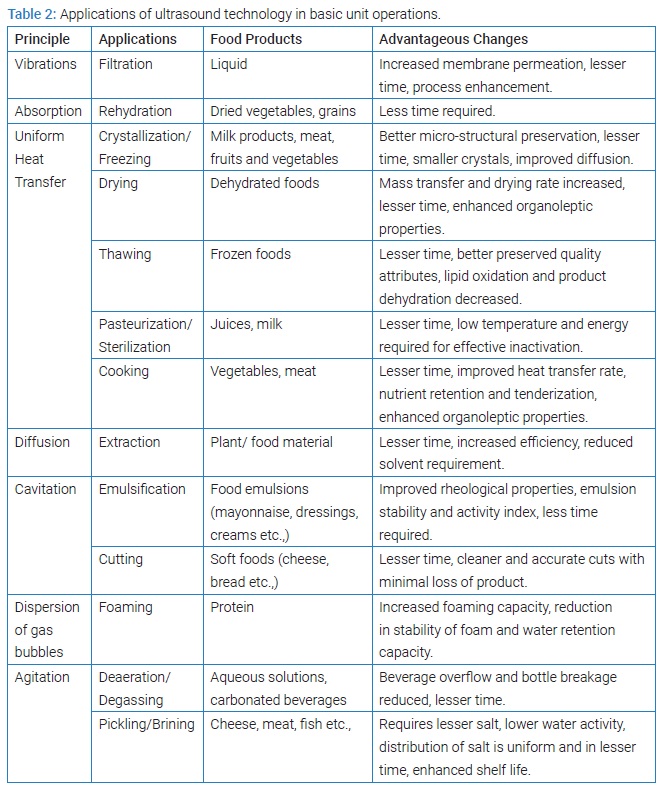

Ultrasound has been explored in the food industry for a wide variety of applications including solid-gas and solid-liquid systems either to replace the tradition process technologies or to enhance their efficiency and yield (via Power Ultrasound) [40]. It has been used for/with osmotic dehydration (with higher drying kinetics), drying (apples, carrots, potatoes, mushrooms etc.,), brining, degassing, cooking, meat tenderization, fermentation, cavitation, rehydration, extraction of nutraceuticals (achieving higher extraction kinetics with supercritical media as well), de-polymerization (inducing permanent changes in rheology), production of nano-emulsions (for delivery of bioactive components), freezing and thawing, in heat exchangers for enhancement of heat transfer (reducing the external resistance to heat transfer), enhancement of oxidation process (wine ageing) etc., [38–42]. It has also been used to modify the textural and microstructural properties of food products and microbial (E. coli, Salmonella, L. monocytogenes, L. acidophilus etc.,) and enzyme (pectin, lipoxygenase, pectin methylesterase, alkaline phosphatase, lactoperoxidase, γ glutamyltranspeptidase) inactivation or acceleration [40]. Ultrasonic slicing by using sonotrode (welding tool) is done to cut biscuits, cheese, fruit and vegetables into perfect slices with minimal product loss [39]. Ultrasonic water bath is used in the processing applications in the food industry for cleaning and sanitation purposes [43]. The applications along with the products and principle are given below in brief (Table 2) [39]. Apart from these, it has found a wide variety of applications in the meat industry, dairy industry, fruit industry and cereal product industry as well as in the honey industry and can be further used in the functional food market due to the extraction abilities [39–40].

Pulsed Light, Pulse Electric Field (PEF) and Pulse Magnetic Field (PMF) Technologies: ‘Pulsed Light’ basically is a radiation of broad spectrum delivered as intense, intermittent, short-duration pulses generated via DC current or by inert gas flash-lamps producing intense light pulses of electromagnetic radiation between 100 nm to 1100 nm [44]. It is a non-chemical, non-ionizing technology for inactivation of vegetative bacteria, spores of fungi, bacteria, viruses and protozoan oocysts, and its safety of usage and penetration ability in foods [15]. When the pulsated light enters the food matrix it is absorbed and the intensity exponentially decays [45]. The total amount of energy absorbed by the food material and initial microbial load will determine the chemical and physical reactions as well as the lethal effects of the pulsated light. High intensity light can lead to the formation of hydroxyl radicals, ozone or hydrogen peroxide which are germicidal in nature [15]. The degradation, up to cell death mechanisms are [46].

Photochemical damage: Pulsed light has UV light portion in it. Similar to its mechanism in the UV-C technology, this UV light portion forms thymine dimers in bacteria, damaging the DNA [15] and thus making it unviable for replication and further reproduction.

Photothermal damage: A difference in the heating and cooling rates as well as absorption characteristics between the bacteria and its surrounding matrix causes localized heating of bacteria. This results in membrane destruction and rupture in the bacterial cell wall due to the bacterial cells acting as vaporization center, especially at higher flux densities (> 0.5 J/cm2).

Photophysical damage: physical damage to the microbial cellular structures causing cell wall damage, cytoplasm damage, membrane rupture etc.,

Microorganisms can revert to a viable but non-culturable state after pulsed light treatment, which can be addressed by incremental increase in the exposure/treatment time [47]. The effectiveness of the pulsed UV light in killing of micro-organisms can be increased with higher energy absorption of the foods. The total dose of energy provided to the food product is adjusted and is usually calculated by the following equation [15].

D = Ep * t * f

Where D is the dose of light energy, Ep is the energy of one pulse, t is the treatment time and f is the pulse frequency in Hertz. The process factors that are important and critical for optimization are the wavelength and light intensity, pulse duration and number, the type of food product along with its specifications such as thickness, transparency and the color specifications of packaging material [15]. It has been used for the treatment of alfalfa seeds, food powders (black pepper and wheat flour), blueberries, mushrooms, eggs etc., inhibiting the growth of micro-organisms such as Salmonella enteritidis etc., [15].

PEF processing is a step further in pulsed light technology in which high intensity electric fields (20 kV/cm to 80kV/cm) are pulsed rapidly (1 millisecond to 100 milliseconds). It acts as an antimicrobial agent via electroporation, i.e., it depolarizes the cell membrane opening the lipid bilayer holes. Due to uncontrolled membrane permeation, the membrane ion concentration is altered leading to fatality of the cell. The controlling factors for optimization include strength of electric field, number of pulses, distance from light source, width of pulse, frequency and duration, input energy and total time of process as well as the temperature, rate of flow, time of hold, and food properties such as pH, conductivity etc., [48,49]. This technology can be utilized for inactivation of bacteria, some spores, mold, and viruses; though the level of inactivation depends on various factors such as growth stage and resistance of microorganisms as well as the supplied energy amount to microbial culture [50]. It improves the shelf life of semi-liquid, liquid and solid food products (salsa, yoghurt, milk, almonds, black pepper etc.,) and helps in better extraction of nutraceutical and bio-active cellular components such as antioxidants, essential oils etc., Further, when used for the pretreatment of roots and tubers, vegetative cells release intracellular compounds and reducing sugars, decreasing the intensity and tendency of food products for over-browning during frying. This application can also be used on sugar beet to increase the extraction of sugar and nutrients [37]. It can also act as a replacer for hydrogen peroxide in treating the packaging materials for decontamination. High intensity PFE treatment has been proved to cause 96.6% inactivation of peroxidase and complete inactivation of polyphenol oxidase in tomato juice, responsible for enzymatic browning [10].

PMF is also used to increase the shelf life of the food products by reducing the microbial load and water activity via the application of static or oscillating magnetic fields creating a non-electrical conductive environment. The food product to be treated is passed through high-intensity magnetic field in the moderate frequency range (5 kHz to 500 kHz) and magnetic flux (5 T to 50 T). Inactivation of micro-organisms can be achieved via changes in the DNA synthesis or ionic drift across the plasma membrane. When the cultures are subjected to the region of intense magnetic field, it causes the translocation of paramagnetic free radicals that resulted in the interruption of microbial metabolic activities and peptide bonds of biological membranes were affected due to their orientation (parallel/ perpendicular) in the generated magnetic field [51]. This technique is advantageous in maintaining the nutrient (especially thermally sensitive) profile of the food product with reduced requirement of energy for processing and can also be used for in-packaged treatment of foods in some cases [51]. It is also used in the fermentation process to control the growth of the undesirable micro-organisms while maintaining the growth of the desired microbes. It has been applied for the inactivation of microbes such as Streptococcus thermophilus in milk, Saccharomyces in yoghurt and orange juice, bacterial spores in bread roll dough, vegetative micro-organisms, E. coli, S. aureus, S. marcescens, P.aeruginosa, S. cerevisiae, P. tinctorius etc., [51]. It can be used for the process operations such as pasteurization, sterilization, freezing, for isolation and separation of proteins, biomass production and for the quality evaluation using Magnetic Resonance Imaging (MRI).

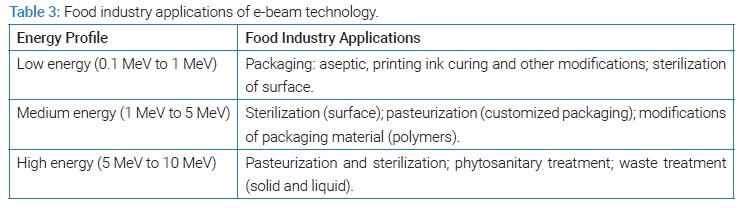

Electron Beam (eBeam) Technology and food irradiation (X-ray & Gamma radiation): Irradiation of food has been one of the most gripping and investigated recent novel processing technology. This includes UV radiation, X-rays, electron beams etc., that use ionizing radiation frequencies for transfer of energy. X-rays (5/7.5 MeV) have significantly higher amount of energy than γ-rays with a higher dose rate (X-ray: ~ 100 Gy/s; γ-rays: ~100 Gy/minute). In US, X-rays are generated by the use of e-beam energies up to 7.5 MeV, for irradiation applications in food [52]. Nowadays, radiation is produced by e-beam technology instead of Cobalt-60 that uses electrons for generation of radiation, being potentially safer for food products to be consumed (due to reduced oxidation effects of gamma rays) [53]. An accelerator, is used to accelerate the electrons generated from electricity at very high velocities (approx. 99.999% of speed of light) gaining up to 10 MeV of energy that penetrate the food packages. With the increasing dose of irradiation, the plasmid DNA, RNA molecules, cellular membranes or the functionally and structurally effective properties of proteins can be affected. Earlier studies showed that a dose of about 0.1 kGy can damage DNA up to 2.8%, enzymes to about 0.14% and amino acids to about 0.0004% [52]. The ions responsible for such effect are different in both the cases:

Direct: when energetic electrons encounter food molecules, they eject the outer electrons (with some energy) off their orbital shells. These electrons cause similar ionization effects to other molecules, dissipating the energy. Since DNA is the largest biomolecule, it gets ionized primarily halting DNA replication. This is seen mainly in frozen foods.

Indirect: splitting of water molecules generates variety of very short-lived, but highly reactive species (free radicals) such as hydrogen peroxide, hydrated electrons and protons, hydroxyl radicals etc.,

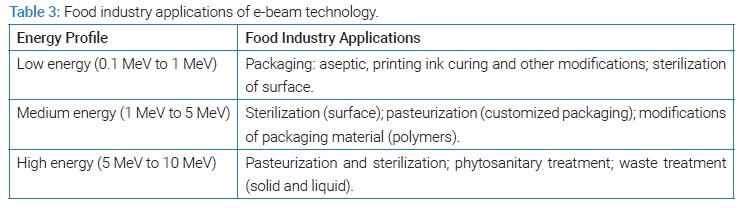

In the food industry, eBeam technology applications are of 3 types: high energy applications (5 MeV to 10 MeV), medium energy applications (1 MeV to 5 MeV) and low energy applications (0.1 MeV to 1 MeV). The food applications are given as such (Table 3) [53].

The technology has been approved by FDA for processing of foods for pathogen control, to prevent microbial contamination of spices, for increasing the shelf life and phytosanitary treatment of fresh produce (instead of methyl bromide), for decontamination of dry food surfaces as well as for pasteurization of meats, oysters, spinach and lettuce [54,55]. Codex Alimentarius has regulated irradiation technology as a useful medium for trans-boundary food transportation [52].

Applications such as the use of Secondary Emission Electron Gun (SEEG) e-beam has been used to treat Salmonella in products such as eggs, ready to eat, peanut butter etc., as well as spores of Geobacillus and Bacillus species [56,57]. It can also address to improve the nutritional profile and maintain the quality of fresh produce where thermal treatment is detrimental e.g. in mangoes [53,58]. Under controlled conditions, it can be used for shelf life extension of ground beef and poultry products, for microbial protection of spices such as pepper, cardamom, nutmeg etc., [52]. Gamma rays and e-beam radiation has also been used for the preservation of Portobello (Agaricus bisporus) mushrooms while maintaining the nutritive components such as sugars and ergosterol [59]. International Atomic Energy Agency (IAEA) has approved the use of food irradiation at the dose of less than 10 kGy for food decontamination but doses up-to 60 kGy have been proved to be non-dangerous and can be used to improve food safety and reduce the economic loss due to crops [60]. In the latest application, e-beam technology can be used to reduce the mycotoxins present in cereals and cereal based products [58].

Chlorine Dioxide: Chlorine di-oxide is used as a sanitizer and is an oxidizing agent. It is generally produced as a reaction product of salt of sodium chlorite/ferric chlorite with organic acid, is environment friendly and has a higher range of adsorption than other aqueous disinfectants. Greater than 99.99% reduction in pathogens of bacteria (E. coli, Salmonella, Listeria monocytogenes etc.,) can be observed on foods and contact surfaces when it is used as an aqueous solution (300 ppm to 1900 ppm). It causes cell membrane disruption (oxygenating the organic compounds in the cells), several amino acid reactions (proteins on reaction with ClO2 initiate cell metabolism interruptions), a disturbance in protein synthesis (due to amino acid oxidation), and the nucleic acid and protein oxidation reactions [61]. It can also be used in gaseous forms to reach hard-to-reach sites of fruits and vegetables. It is effective in a wide range of 3pH to 8pH and doesn’t affect the nutritional and organoleptic attributes of the food product. But the antimicrobial activity can be optimized via changes in temperature, depending on the target microorganism and its nature [61]. It is a light sensitive gas, and its efficiency is based on factors such as time, temperature, relative humidity, gas concentration, surface integrity of the produce etc., It has several applications in the fruit (blueberries) and vegetable (tomatoes, carrots) industry as well as meat and poultry industry. It has been approved by US FDA since 2006 for the use in post-harvest agricultural produce [62]. It has seen to cause slowing of enzymatic browning in freshly cut fruits and vegetables, lowering metabolism in fresh-produce, preventing fruits form softening (preventing protein synthesis in cell walls) etc., [61].

In the packaging industry, it is used for antimicrobial packaging: the precursors are allowed to react and the resulting gas formed (ClO2) is injected into the bag/ container before to closing/ sealing. In the package environment the gas mixes and disperses easily and has an ability to diffuse into product (fresh produce and meat) surfaces and films but is only effective for short duration [61]. If the initial concentration added is high, it can damage the quality and sensorial factors of the food products. A substitute method involves the development of sachet-type insert containing precursor chemicals, and the use of multilayered ‘label’ kept in the internal side of the packaging which is composed of individual gelatin/ pectin layers impregnated with reactive precursors (organic acid + sodium chlorite salt) that breaks on application of mechanical strength releasing ClO2 [37]. Gaseous ClO2 can be encapsulated in α- Cyclodextrin, silica gel, gelatin, activated carbon, cyclodextrin etc., releasing at specific temperature and relative humidity [61].

Ozone: Ozone gas (O3) is used for the ozonization process when the food is disinfected on being subjected to the radiations. It is generated by the following method via a high electrical energy source (Corona Discharge/Cold Plasma Method) or by using UV/ gamma radiation [63].

O2 → 2O (with two unpaired electrons) [under UV light/ high electric arc]

O2 + O− → O3 (unstable)

This instability of the ozone gas is responsible for its high reactivity which is responsible for its beneficial effects when used immediately or even later with the decomposition products (free radicals). The antimicrobial effect of ozone on both gram-positive and gram negative microbes, spores and vegetative cells is due to its strong oxidizing effect (2.07 mV) which can also be used to improve the protein and starch functional properties by structural modifications and it is advantageous since there are no toxic residues left after the processing operation [63,64]. It acts on the glycolipids and glycoproteins of the cell wall, cell membrane and the nucleic acid (DNA and RNA modifications) and enzyme systems of the microbes [63].

The two main effects are: affecting the sulfhydryl groups amino acids in enzymes and peptides, proteins, PUFA of cell membranes, which are responsible for the formation of pores in cell wall/ membrane leading to oozing out of internal cell material and movement of water inside the cell causing cell bursting [63]. It has been proved effective against the micro-organisms such as E.coli O157:H7, A. acidoterrestris, T. constaneum, Sitophilus oryzae, Sitophilus zeamais, A. flavus, A. parasiticus, F. graminearum etc., It has achieved the status of ‘Generally Regarded as Safe’ (GRAS) status by the US FDA for applications of drinking water disinfection, during wastewater treatments and as a disinfectant/sanitized for foods. When used under proper conditions of temperature and pH as well as food constituents (depending on the food product and target microbe), its application includes fruits and vegetables, juices, grains, meat, fish etc., for increasing their shelf life while maintain the quality and nutritional attributes, though some variations can be seen in the level of components such as Vitamin C, caffeine, cinnamic acid, polyphenols, anthrocyanins, cyanidine 3-glucoside, ascorbic acid content pertaining to different food products [63]. It has also been used as an anti-fungal agent in cereals and is used for the destruction of mycotoxins (e.g. aflatoxins) in cereals and peanuts [63,65]. It can also be used for detoxification of pesticides such as chlorpyrifos, cypermethrin, hexaconazole, azoxystrobin, fenitrothion etc., in products such as olives, olives, grapes, cherry tomatoes, lettuce, strawberries etc., [63].

High-Pressure Carbon-dioxide (CO2): This is a mainly a non-thermal pasteurization/sterilization technique that uses high pressure (<50 MPa) carbon-dioxide (gaseous, liquid or super-critical) on liquid and solid food products for inactivation of enzymes (polyphenol oxidase, lipoxygenase, pectin methylesterase), removal of spoilage and pathogenic micro-organisms and avoid the effects of thermal treatment technologies [66]. The factors on which the efficiency depends mainly on the temperature and pressure of CO2 applied as well as the water activity of the food product under consideration. It can also be used for improving the functionality of beverages, development of polymers, extraction of bioactive components (super-critical fluid extraction, SCFE), preparation of extruded snacks, encapsulation, bakery, texturing, water cleaning and disinfection as well as removal of pests and insects during storage of commodities. Carbon dioxide is GRAS and is non-toxic, inert, and inexpensive. The mechanism of action has been regarded under three reasons: oxygen displacement generating anaerobic environment that adheres the cell processes; acidification (formation of carbonic acid) and solubilization causing decrease in pH; and cell rupture due to the increased internal pressure [66]. It is responsible for impacting the protein structure more than the usual thermal technologies, a reason for modifications in food products containing proteins and enzymes.

Advanced thermal processing technologies

Electrical properties like dielectric constant and loss factors have been used to generate heat in the dielectric material like food material. These properties are used to obtain fast and uniform heating when food materials are exposed before radiofrequency/microwave or directly pass electrical current through food material where food itself creates resistance to flow of electric current or act itself as a heater. Therefore, foods are processed very fast or achieve 5 log reduction, preserve nutritive value and sensory quality.

Radio Frequency (RF) and Microwave Technology: RF (10 MHz to 50 MHz) and microwave (2450 MHz and 915 MHz) energy, like visible light, can be focused into beams and transmitted through hollow tubes, are non-ionizing radiations and depending upon dielectric properties of the materials, can be reflected or absorbed. Microwave can also transmit through packaging materials like glass, ceramics and thermoplastics without being absorbed. When the electromagnetic energy is transferred directly to the dialectic (food) material, it subsequently generates heat due to dipole rotation as well as polarization of ions. In microwave, polarity alternates rapidly (at 2450 MHz, the polarity changes at 2.45 x 109 cylcles/second). In order to maintain alignment with this rapid change in polarity, the polar (e.g. water) molecules rotate. This rotation of molecules leads to generation of friction between the molecules and the surrounding medium resulting in the generation of heat. The commonly applied RF technology in industries and lab uses two types of heat energy generation methods: free running oscillator or 50 Ω systems [67]. The penetration depth of RF his higher than microwaves due to its longer wavelengths which can be used for better and homogeneous heating as well as more stable control over product temperature and thus, is a preferred choice depending on the application [68].

The most important application of RF is the pasteurization of egg, to preserve the quality of eggshell as well as inactivate Salmonella (by 99.999%) while unaffecting the albumin and maintaining the final yolk quality and functional factors [37,69]. Other applications include drying (heating is homogeneous with a higher penetration depth, and more stable product temperature control), heating of bread, post-baking in biscuit industry and pasteurization of yoghurt, processing of fresh products with high water activity and treatment of meat. It has been used on products like wheat flour, peaches, juices, crackers, pepper spice, almonds, potatoes, rice, lentils, legumes, walnuts etc., for the inactivation of a wide variety of micro-organisms [68,70,71]. It has been shown that RF heating leads to the reduction of pathogen in agricultural materials by 4 log cycle; inactivation of Bacillus cereus and Clostridium perfringens in pork meat; E. coli, Listeria innocuous in milk; Clostridium sporogenes in scrambles eggs etc., [68]. It can also be used for the postharvest pasteurization/disinfection of agricultural commodities for replacement of fumigation, seed treatment as well as processes like thawing/tempering of fish and meat, sterilization/pasteurization (especially for low-moisture foods), roasting of peanuts, blanching of apples, mustard, vegetables (increases ascorbic acid content to achieve highest levels of Vitamin C) etc., [67,68,71,72]. A packaging application involves the use of Radio Frequency Identification (RFID) sensors for selective detection of freshness and bacterial growth in foods such as milk, fish etc., [73]. This field of study is being improved by inducing the computer simulation for optimization that can be applied for a variety of applications [68,74].

Microwave heating reduces the cooking time and energy consumption with improved food properties (sensory, chemical and physical). Optimization of effective heating is dependent upon depth penetration value, attenuation and dielectric loss factors. It can completely inactivate microorganisms (such as E. coli, Salmonella enterica, Enterococcus spp., Listeria monocytogenes) in higher doses and effectively inactivate enzyme activity (such as enzymatic lipolysis, activity of polyphenol oxidase, peroxidase, pectin methylesterase etc.,) [75]. In 2011, FDA also approved energy at 915 MHz as Microwave Assisted Thermal Sterilization process (MATS) energy for food pasteurization or sterilization of packaged foods when immersed in water, which eliminates food pathogens and spoilage microorganisms in about 5 minutes to 8 minutes [43]. The use of microwave technology in applications such as heating, drying (with shorter processing times and more porous structures), pasteurization and sterilization of fruits (banana, apple, strawberry, blueberries etc.,), vegetables (potato, onion, green beans, broccoli, cauliflower etc.,), rice (improves quality and reduces growth of pests and mildew) and meat products (sardine fish, sea cucumber, foal meat, beef slices, bacon, meat, salmon etc.,) as well as packaging operations has been extensively developed over the years [75,76]. It can lead to more uniform meat protein coagulation, less shrinkage of product and renders fat of high quality with an overall improved color, appearance and taste [76]. It also helps maintenance of antioxidant activity, reduced leaching of vitamins and higher levels of bioactive components as well as the pleasantness of appeal when used for operations such as blanching [76]. It is also effective for processes such as tempering and thawing of frozen products and can be used for the extraction of bioactive components such as pectin from apples, phenolic antioxidants from skin of peanuts, tea polyphenols and caffeine etc., (Microwave Assisted Extraction, MAE) under proper time temperature conditions [76]. When applied on heat fouling-sensitive foods such as milk concentrates, it was found out that microwave heating reduces the denaturation of whey proteins and β lactoglobulin and deposit formation of reconstituted skim milk concentrate, retaining better product properties [77]. It can be combined with techniques such as ultrasound in vacuum frying system, generating higher drying efficiency and better quality aspects of the fried products, with reduced uptake of oil, lower shrinkage and water activity and improved color and crispiness of the end product [78]. Another recent application involves the use of microwave technology to induce structural transition (β-sheet structures to α helix and random coil structures) and improving the foaming properties (due to increased viscosity and improvement in the egg white protein) of egg white powder [79].

Ohmic heating: In this, processing of food takes place in a continuous system and is better suited for products in broad pH range and with larger particles which are conventionally difficult to heat-process due to insufficient heat penetration [80]. In ohmic heating, alternating current (AC; 50 Hz to 60 Hz) passing through a conducting solution (e.g. brine) generates heat. The product is kept in the conducting solution between the electrodes (Cr/Mn/Ni/Fe) that pass the AC current. It can be done in batch configuration, transverse or collinear ohmic configurations [81]. The electrical resistance of the food (Joule effect) causes volumetric heating with high efficiency (<90%) [82]. Heating efficiency of a material is based on its electrical conductivity and is given by [83].

σ = (L/A) * (I/V)

where: σ – electrical conductivity, L – spaces of 2 electrodes, A – cross sectional heat cell material surface, I – AC current, V – material voltage.

Micro and macro structural changes are observed in the food products are: migration of moisture, gelatinization of starch, denaturation of proteins etc., depending upon the process conditions and treated material composition. The non-thermal effects include electroporation and electrical breakdown, which alters the cells and tissues and in turn, texture of some food materials (esp. fresh foods). Thus, optimization of ohmic process parameters such as electrical specification, process time, temperature, product formulations etc., is necessary to carefully balance the kinetics of texture softening and other beneficial aspects [84,85]. The major advantage of ohmic heating is the consistency in heating between the inside and outside of the food product (sometimes enhanced via pre-treatments) with solid pieces and liquid heating uniformly, thus causing lesser heat damage [82]. It can be used for extraction of components such as inulin, tepurang fruit oil, anthrocyanins and phenolic compounds (inducing cell-membrane electro-permeability), pasteurization, blanching, fermentation, sterilization, dehydration, thawing, enzyme (pectin methylesterase, peroxidase, tyrosinase, polyphenol oxidase, lipoxygenase, lycopene, β carotene) inactivation, and evaporation [81,82]. It can inactivate pathogenic microbes (E. coli, Zygosaccharomyces rouxii, Alicyclobacillus acidoterrestri, Listeria monocytogenes, Salmonella typhimurium etc.,) and enzymes (tyrosinase, polyphenol oxidase, lipoxygenase), improves thawing process, and prevents decline in the functional, nutritional and sensory properties of food. It has been used as an alternative technique for sweet whey processing and for the processing of other dairy products and can alter the water absorption index, water solubility index, thermal properties and pasting properties of food components [86–88]. This technology has been modelled and used on a range of food products such as fruits, vegetables, cereals, solid-liquid mixtures, eggs, fish products, meat products etc., [81]. This is one of the earlier technologies of the 21st century along with HPP, which is considered as a revolutionary technique to heat foods in a continuous system but hasn’t found much appreciation in all these years [89].